Choosing the right blind rivet

Blind rivets and blind riveting pliers are also called pop rivets and pop riveters. They are used to fix together hard materials such as sheet metal and metal objects when you have access to only one side of the material – for example, when you fit mudguards on your car or gutters on your house. The blind rivet you choose depends on the environment in which it will be used, as well as the materials you will be working with. So you need to find out what kind and what size of blind rivet you need.

Blind rivets for different applications

Stainless blind rivets

Stainless blind rivets are made of ISO 304 grade stainless steel. They give a strong and durable join. They usually last longer than the materials being joined together and are good outdoors, for example, to attach number plates or silencers to vehicles, or repairing rusty metal surfaces.

Waterproof blind rivets

Waterproof blind rivets are made in one piece to prevent leakage between the composite materials. They are well suited for fixing and repairing guttering or assembling shower panels, for example.

High performance blind rivets

High performance blind rivets have a wide range of applications with a sustainable result. They are good for attaching signs, joining sheet materials and for various repairs.

Coloured blind rivets

Coloured blind rivets are specially adapted for attaching number plates and other accessories to vehicles. They can be matched to the colour of the vehicle to conceal them.

XL blind rivets

XL blind rivets have an extra-large head that provides a larger surface area for fastening and extra resistance. They are good for joining soft materials such as leather, rubber and plastic with hard materials.

Standard blind rivets

Standard blind rivets are versatile and provide reliable results for everyday projects.

Choosing the right size of blind rivet

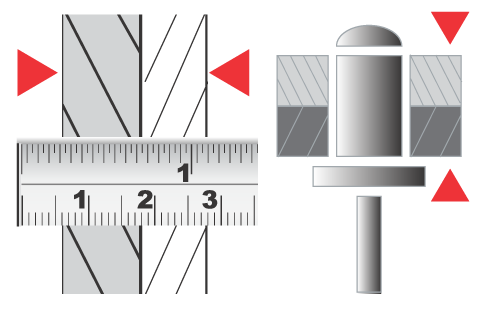

Step 1: Measure the grip range. The grip range corresponds to the total thickness of the materials being joined together.

Step 2: Use the table below to determine the length of the blind rivet. The greater the diameter of the blind rivet, the stronger the join.

Example: If you are going to join two metal plates with a grip of 13 mm and want to use a 4.8 mm diameter blank rivet, the rivet must be 18 mm long.

| Ø mm | Your measured Grip Range |

Required rivet height (mm) |

| 3,2 | Between 2 and 4 mm | 8 |

| 4,0 | Between 2 and 5 mm | 8 |

| 4,0 | Between 6 and 9 mm | 12 |

| 4,0 | Between 8 and 10 mm | 14 |

| 4,0 | Between 9 and 12 mm | 16 |

| 4,0 | Between 12 and 15 mm | 18 |

| 4,8 | Between 4 and 7 mm | 10 |

| 4,8 | Between 6 and 9 mm | 12 |

| 4,8 | Between 8 and 11 mm | 14 |

| 4,8 | Between 9 and 12 mm | 16 |

| 4,8 | Between 12 and 14 mm | 18 |

| 4,8 | Between 14 and 16 mm | 20 |

| 4,8 | Between 19 and 22 mm |

25 |

Read more:

Guide: How do I use blind riveting pliers?

Guide: Good to know about blind riveting pliers